Keeping industrial machinery running smoothly isn’t just about routine servicing anymore. With growing pressure to reduce downtime and make smarter use of maintenance budgets, operations teams are turning to high-tech diagnostic tools like thermal imaging and acoustic imaging cameras.

Both offer valuable insights, but in very different ways. This blog explains how each works, what they’re best used for and how Thermascan applies these tools to help clients avoid costly breakdowns and enhanced reliability.

What is Thermal Imaging?

Thermal imaging cameras detect infrared radiation the heat naturally emitted by objects and convert it into a visible image called thermogram. This allows engineers to visualise heat signatures in machinery, wiring, insulation and other components without needing to touch or dismantle anything.

Unlike traditional spot thermometers, which measure temperature at a single point, thermal cameras are able to scan thousands of data points in real time. This gives a complete view of how heat is distributed across a surface or within a system, ideal for spotting irregularities before they lead to serious equipment failures.

Common Uses in Industrial Settings:

Identifying hot spots in electrical panels

Monitoring motor performance

Checking the integrity of insulation and ductwork

Preventing fire risk from overheating components

At Thermascan, we use premium FLIR cameras to conduct thorough thermographic surveys, helping clients identify and fix early-stage faults across a range of industrial environments, all without needing to pause any type of operations going on.

Why Do Colour Palletes Matter in Thermal Imaging?

A thermal palette is the colour scale applied to thermal images to make temperature variations more visible. Choosing the right palette is key to interpreting results quickly and accurately.

Common palettes include:

Ironbow: A smooth gradient from black through red to white, ideal for highlighting hot spots

Rainbow: Bright colour contrast for detailed fault detection

Greyscale: Simplified visuals, often used in formal reports

Thermascan engineers typically use Ironbow for inspections and Greyscale for reporting, striking a balance between clarity in the field and easy communication with stakeholders.

The right palette can make anomalies stand out clearly, for instance, a bearing that’s beginning to overheat will appear far brighter than surrounding equipment, helping maintenance teams act quickly.

What is an Acoustic Imaging Camera?

Where thermal cameras visualise heat, acoustic imaging cameras visualise sound, specifically ultrasound, which is produced by faults like compressed air leaks or partial electrical discharge.

Using arrays of highly sensitive microphones, acoustic cameras detect high-frequency sound waves, even in loud environments. This data is processed and displays as a live acoustic imaged overlaid onto video, showing exactly where a fault is occurring.

Key Applications:

Detecting compressed air and gas leaks, which can waste thousands of pounds in lost energy each year

Spotting early signs of electrical discharge, such as corona or arcing

Listening for bearing wear, gearbox misalignment or valve leakage

Thermascan integrates acoustic imaging into predictive maintenance programmes to help clients reduce energy losses and extend equipment life, often identifying issues long before they’d become audible or visible by conventional means.

Which Camera Is Best For You?

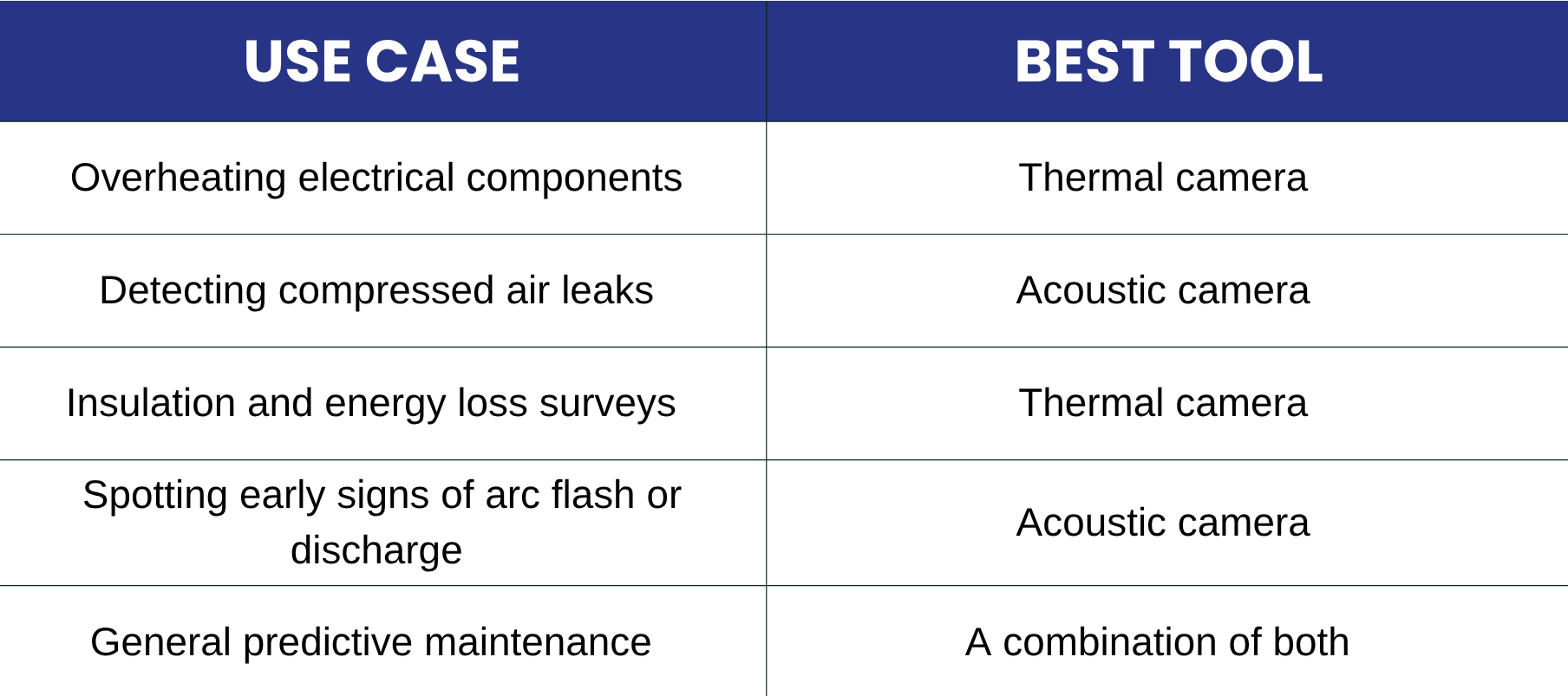

Each technology serves a specific purpose. Choosing between them depends on what you’re monitoring and what faults you need to prevent.

In many cases, the best results come from using both technologies together. Thermascan engineers frequently conduct dual surveys, using thermal imaging to detect temperature-based issues and acoustic imaging to uncover hidden energy losses.

In many cases, using both technologies together delivers the most comprehensive results. Thermal imaging highlights temperature anomalies that may indicate electrical, mechanical or insulation issues, while acoustic imaging pinpoints high-frequency sounds produced by air leaks or partial discharge. By combining both tools, Thermascan engineers helps clients spot hidden inefficiencies and risks that would otherwise go unnoticed, supporting more effective maintenance planning and long-term operational savings.

Smarter Maintenance Starts with the Right Tools

Operations Directors are under pressure to keep plants running efficiently, safely and cost effectively. Choosing the right condition monitoring tools, and using them proactively, can make all the difference.

Thermal and acoustic imaging are powerful, non-invasive solutions that support predictive maintenance, extend asset life and improve uptime. Whether you’re managing a single site or multiple facilities, Thermascan can help you build a smarter, data-led maintenance strategy.

Take a look at our website for our full range of thermal imaging surveys, or learn how acoustic imaging can cut energy losses, if you need further advice, make sure to contact our team for more information.