Refractory Thermal Imaging Surveys

Thermographic surveys are not just cost-efficient, they’re also a non-invasive way to identify issues before they become a problem, ensuring that you save time and money.

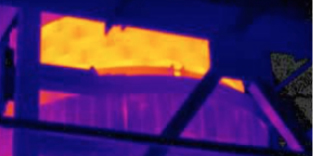

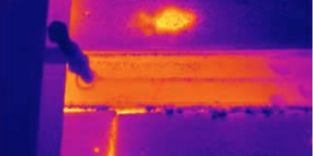

One of the uses of thermal imaging is for refractory surveys, as the technology allows for routine non-contact inspections of installations that include refractory material, which helps to reduce safety risks and machinery downtime.

The Importance of Refractory Surveys for Businesses

Our thermographic surveys are critical for industries like manufacturing, including sectors that use machinery like boilers, kilns, incinerators, mill ladles, and furnaces.

After all, refractories are just as prone to problems and malfunctions as other sectors, such as overheating, slag build-up, leaks, etc., but thermal imaging can help you to identify these and other issues.

Whether as part of your predictive maintenance plan or as part of an inspection, thermal imaging can help you to avoid expenses, equipment breakdown and dangerous faults in machinery.

If you’re interested in having a plan in place to stay on top of your equipment, then you can rest assured that our team of level II certified engineers can carry out refractory surveys on a case-by-case basis or as part of a plan – you decide what works for you!

And, with our Teledyne FLIR thermal imaging cameras (including thermal imaging camera hire), you can inspect machines and find faults before they develop and become costly.

Enjoy the peace of mind that comes from knowing that your equipment is running smoothly, and all systems are performing well.

What Do Refractory Thermal Imaging Surveys Help with?

There are several things to look out for when it comes to refractory surveys. Typical inspections include, but are not limited to, the following:

Examining the overall condition of vessels, including rotary kilns, steel ladles and process furnaces.

Checking furnace tube condition and operating temperatures.

Visibly determining the presence of cloggy and excessive coking.

Refractory linings tend to have short lives, for instance, as they wear over time and because of the high temperatures they’re exposed to. In order to ensure the safety of staff and equipment – and to avoid having to spend thousands on new machines – thermal imaging surveys can step in and detect problems with time to spare.

There are many other uses for thermal imaging in refractories, and we have many cameras that can meet your specific demands. Besides purchasing or hiring, depending on what works best for you, you also have the option of getting new or used equipment.

Enquire Today About our Refractory Surveys

Want to learn more about our refractory thermal imaging surveys and how they can help your day-to-day? Or how they can help you to create a great predictive maintenance plan?

Get in touch with us on 01234 219421 and we’ll be happy to discuss this with you. We're always on hand to answer all your questions, so message us at sales@thermascan.co.uk today.

Looking for your own surveying camera?