How Thermal Cameras and Technology are Transforming the Waste Management Industry

Waste management sites face ongoing challenges. With growing volumes and changing materials daily, fire risk is a major concern. Traditional safety measures remain important, but many operators now want greater visibility of temperature risk across stored materials and processing areas.

Thermal imaging has become an important part of this conversation. Used correctly, it provides visibility that standard visual checks and conventional alarm systems cannot.

Why Waste Sites Are Prone to Hidden Fires

Waste facilities face unique conditions that make fire detection difficult. Heat often builds up deep within stored material, away from the surface. Traditional fire detection systems rely on smoke or flame, which appear late in the process.

Several common factors increase fire risk on waste sites:

Large volumes of compacted material that trap heat

Organic waste that generates heat as it decomposes

Lithium-ion batteries hidden in mixed waste streams

Mechanical processes that create friction and stress

Limited visibility into enclosed or high-risk areas

Because of these conditions, fires often start below the surface. When combustion indicators become visible, response measures are typically more complex and disruptive. Infrared temperature monitoring helps bring that line of sight forward.

What Thermal Imaging Detects That Other Systems Cannot

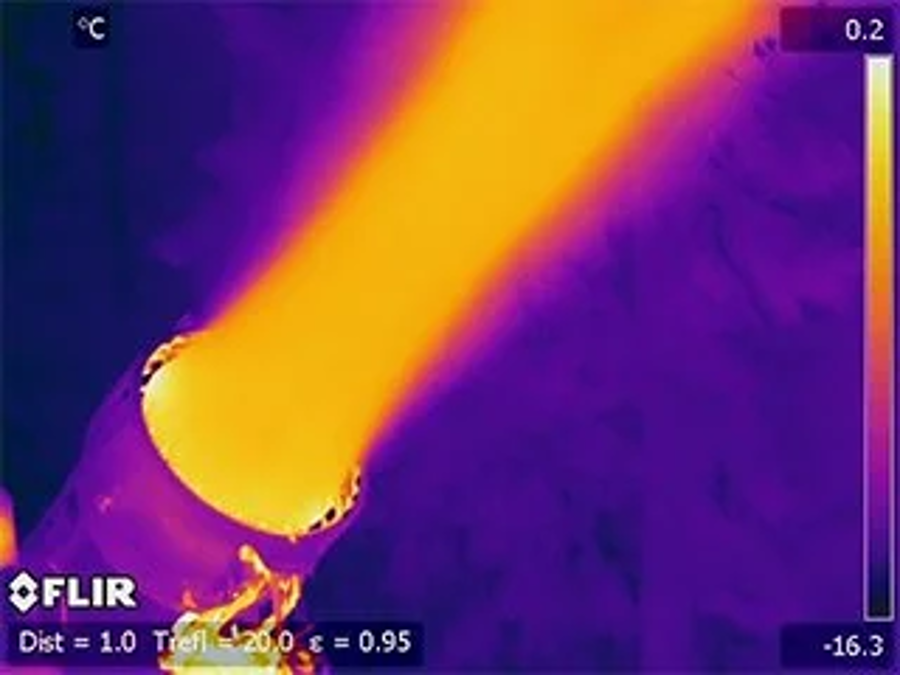

Thermal imaging cameras measure surface temperatures and display them as visual images. Hotter areas appear clearly against cooler surroundings, even when there are no visible signs of fire.

It is important to understand the scope of technology. Thermal cameras do not detect heat inside waste piles. They measure temperature patterns. However, surface variation is often the first measurable indicator that internal conditions are changing.

On waste sites, thermal imaging is used to detect:

Heat build-up within waste piles or bunkers

Abnormal temperature increases on conveyors or machinery

Overheating caused by battery damage or compression

Early thermal activity that precedes smoke or flame

This non-contact heat scanning enables operators to track temperature changes rather than rely on visible fire indicators. By continuously monitoring temperature trends, the system supports early fire detection.

Addressing Common Questions About Thermal Imaging

Does thermal imaging trigger false alarms from people or vehicles?

Modern thermal systems can tell the difference between normal heat sources and risk indicators. Software filtering reduces false alarms from staff, vehicles, and mobile plant.

Can thermal imaging see through waste materials?

No. Thermal cameras only measure surface temperature. Their value lies in detecting surface change that signals developing heat beneath.

Is thermal imaging suitable for all waste sites?

Suitability depends on layout, waste composition, and operational processes. A professional assessment determines where monitoring delivers measurable value.

Why Insurers and Regulators Pay Attention to Thermal Monitoring

Fires at waste sites can cause big financial and environmental problems. As a result, insurers now expect operators to demonstrate active risk management.

Thermal imaging can form part of a broader fire prevention strategy by:

Supporting documented risk assessments

Providing verifiable proof of high risk area monitoring

Supplying recorded thermal data for reporting

Reducing reliance on reactive emergency response

While requirements differ, preventative monitoring is viewed positively in audits and insurance reviews.

The Importance of Professional Assessment and Installation

Thermal imaging is only effective when systems are correctly specified, installed, and maintained. Camera positioning, site conditions, and data interpretation all influence performance.

A professional thermal survey ensures:

Cameras are positioned to monitor correct risk zones

Environmental factors such as airflow are considered

Data is interpreted accurately

Systems integrate smoothly with existing site operations

This is why technical experience matters. The technology is precise, but its value depends on correct application.

How Thermascan Supports Waste Management Monitoring

In a sector placing increasing focus on steady prevention rather than reactive intervention, structured thermal monitoring plays an important role in maintaining safer, more predictable waste operations.

Thermascan offers professional thermal imaging surveys and monitoring solutions for complex commercial and industrial environments, including complex waste management sites. Our focus is on accurate data capture, clear reporting, and practical implementation that supports day to day risk management.

If you are reviewing fire prevention controls or assessing monitoring options, our team can provide clear, site specific guidance.

Contact Thermascan to discuss a thermal imaging survey or monitoring solution aligned to your operational requirements.

With this in mind, thermal technology, in particular, software such as TST Fire Indoor software is becoming a popular choice within the waste detection sector. Waste Management Services such as London Waste are investing in this technology now to continuously monitor areas with various levels of risk with minimum hassle and maximum precision. London Waste currently look after just over seven North London boroughs with high turnovers of waste and recently won in the category of ‘Health and Safety Best Practice’ at the CIWM Sustainability and Resource Awards 2017.