Infrared Inspections

Whatever the industry, there is always a need for rapid response, to help minimise damage in the workplace and also overall costs.

Thermal imaging is the perfect tool to help with this by detecting early signs of failure by scanning for anomalies.

What is Predictive Maintenance?

Predictive maintenance a way of predicting when machines or equipment may fail, allowing maintenance to then be conducted before the failure occurs.

These predictions are based on temperature measurements that evaluate the machines by detecting temperature anomalies in hot and cold spots, using the process of condition monitoring to keep track of possible changes.

How does Predictive Maintenance work?

By using condition monitoring equipment like infrared cameras, predictive maintenance can be carried out by assessing equipment and machinery ‘around the clock’ in a fast and low-cost manner.

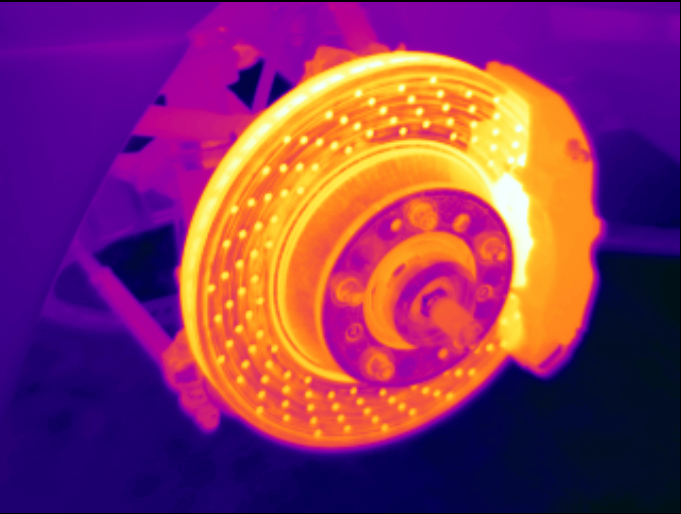

Thermal Imaging cameras are able to capture infrared images of mechanical components within the machinery including, motors and pumps. Once the components have been identified, it is then easy to determine problems within them like bearings or gearboxes.

By following this process, managers can respond quickly to prevent these potential damages from becoming costly failures further on.

How can I use thermal imaging to detect faults?

Infrared cameras can be used to carry out low voltage inspections of electrical equipment by identifying temperature increases in electrical connectors, this shows where the connectors have become loose that could then result in failure of parts. By finding the high temperature given off by the loose connection you are able to save money and pinpoint the exact location of the problem.

Thermography can also be helpful when conducting inspections of connectors carrying high voltages, to detect issues. By identifying the temperature difference you can then work out what actions need to be implemented before the problems occur. The image captured on the thermal camera will also help to clearly indicate where circuit breakers and power lines of high voltages are situated to help assess other potential issues.

Thermal equipment is often used within industries to highlight issues with mechanical systems to detect overheated bearings shown by high-temperature readings, demonstrating where strain has occurred on the motor. Thermography cameras can also detect lubrication issues and misalignment where this could result in a reduction in workflow pace if not detected.

Thermal Imaging is great for plumbers detecting faults such as leaks in pipes or blockages in insulation. The cameras can survey a large area quickly. This means you don’t need to rip up floors and remove each part of a pipe to find a blockage as thermal equipment have the ability to detect temperatures through flooring (not carpet) and in walls where pipework is hidden.

Why Choose thermal imaging?

Easy to use equipment

Just like a standard camera or a mobile phone, thermography cameras are based on the same basic hand-held principle of ‘point and shoot’ to capture images, they also have the ability to record video too.

Used during systems operations

You don’t need to worry about shutting down plant equipment for predictive maintenance to be conducted. The thermal cameras will still be able to detect faults accurately.

Locate the exact problem areas

Thermography can identify precise locations where anomalies are situated, helping you to fix the problem promptly before it gets worse.

Equipment is versatile

If you have fixed thermographic cameras to carry out condition monitoring, they have the ability to automatically find temperature anomalies automatically. With options to sound alarms when certain temperatures are reached and detected by the cameras, you can sort the issue immediately, removing the risk of unplanned outages.

You don’t need to be an expert

If you know the standard temperature of the equipment being assessed you can detect temperature differences quickly and easily by finding the hot and cold spots that shouldn’t be there. Once the temperature differences have been found, these then tell you where the problem is situated and why it may have occurred.

Where can I use predictive maintenance?

Identify construction faults, moisture detection and areas with mould and mildew.

Detect poor connections, internal fuse damage and electrical leakage.

Seek out overheated bearings, equipment and machines, highlight misalignment issues

Highlight insulation breakdowns, blockages in pumps, pipes and valves

Fault detection of overheated engines, friction detection, heated seats and the wearing of brakes

Find mechanical breakdowns, coolant blockages and faults in fuel systems

Determine leakage, holes in pipes, pump damage and motor defects

Predictive maintenance monitors conditions of machinery and equipment, by using thermal cameras you can do this quickly and as a low-cost checking method; helping to keep your business run smoothly continuously.

If you need help finding the right inspection tool for you, get in touch with one of our friendly advisers who will talk you through the best camera for you!